Case studies & Applications, Industry Insights

Why Most PCB Projects Fail on First Iteration

Every engineer hopes their first PCB design will power on and “just work.” But in reality, most PCB projects fail on first iteration or don’t make it past the bench without major issues. A wrong footprint, unstable power rail, or misrouted signal is all it takes to turn a promising project into weeks of debugging, wasted prototypes, and blown deadlines. For startups, that can mean missing a product launch; for consulting firms, it can mean losing a client.

So why do so many PCB projects fail on the first iteration? More importantly, how can you reduce the risk of your design becoming another costly re-spin? In this article, we’ll break down the most common reasons first iterations fail, the hidden costs teams rarely calculate, and the best practices that can help you design for success. Along the way, we’ll show how modular design approaches—like Quickboards’ pre-verified schematic and firmware blocks—can dramatically improve your chances of getting it right the first time.

The cost of a failed PCB first iteration

Every PCB re-spin comes with a heavy price. On average, a redesign can add 4–12 weeks to a project’s schedule—time spent debugging, revising schematics, re-drawing layouts, and waiting for a new batch of boards to be fabricated and assembled. Each iteration can also cost thousands of dollars in wasted prototypes, tests, and engineering hours. For startups, these delays can be devastating, leading to missed deadlines, lost contracts, or even jeopardizing an upcoming product launch.

Common reasons PCB Projects fail on first iteration

Component selection pitfalls

One of the most common ways to sink a design is with the wrong component choice. Either the footprint doesn’t match, the part is going obsolete, or supply chain shortages make it impossible to source. Even a single incorrect package assumption can lead to a non-functional board.

Schematic Mistakes

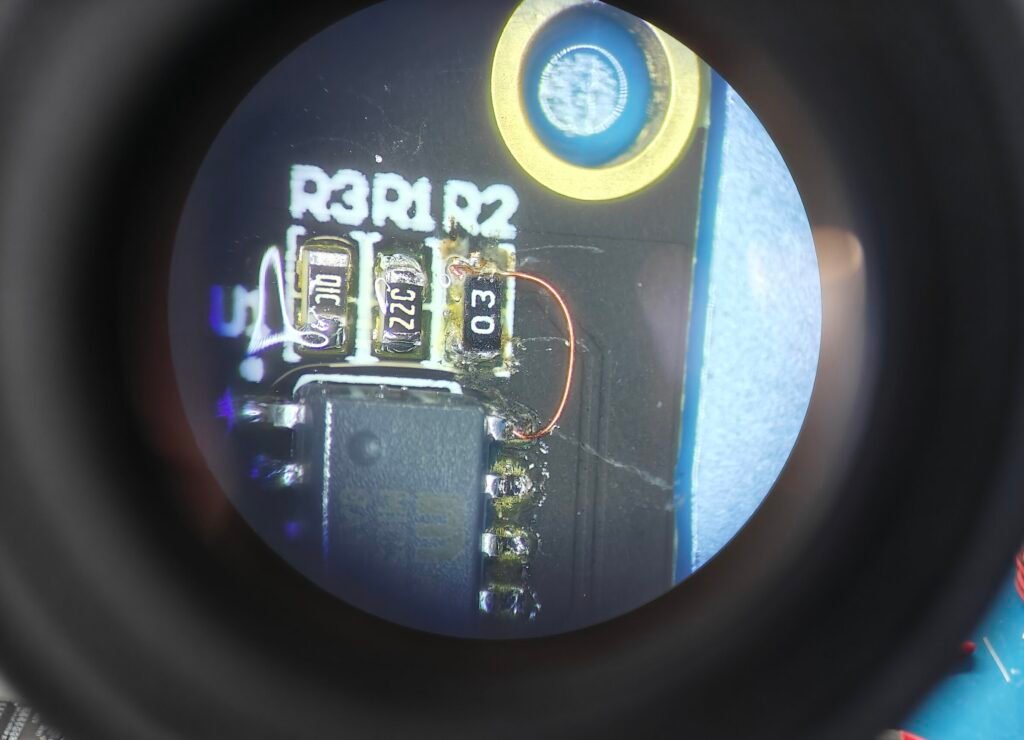

It only takes one overlooked connection to ruin a board. Bad connections, forgotten pull-up/pull-down resistors, or missed decoupling capacitors can all mean the difference between a board that boots and one that’s dead on arrival. These mistakes are easy to make under time pressure, but fixing them requires a full re-spin, wasting both time and budget.

Layout Oversights

A flawless schematic can still break once it’s translated to copper. PCB Projects to fail on first iteration due to Poor ground planes, bad trace routing, or ignoring clearance rules often create hidden flaws that only show up once the board is powered. Engineers who skip layout reviews often discover too late that their design is not manufacturable—or worse, stable in the lab and makes it to production, but unstable in the field.

Power integrity failures

Power delivery is where many first iterations collapse. An unstable regulator, missing bulk capacitance, or underestimated inrush current can cause rails to sag or oscillate. These aren’t just minor issues—they can leave the board unable to even power on, forcing a full redesign.

Signal integrity issues

High-speed buses don’t forgive sloppy design. Crosstalk, impedance mismatch, or long stub traces can break communication lines, leaving processors and peripherals unable to communicate. What looked fine in the schematic becomes a failure on the bench, and fixing it often means days spent troubleshooting before a re-design.

Rushing to fabrication

Under deadline pressure, teams often skip simulations, reviews, or even a second set of eyes on the design. The board goes straight to fab in the hope it “just works.” More often than not, it doesn’t—turning what should have been a proactive check into an expensive mistake.

Poor collaboration

PCBs also fail because teams don’t stay aligned. Miscommunication between hardware, firmware, and mechanical engineers leads to mismatched connectors, misplaced components, or firmware that doesn’t run on the final board. When collaboration breaks down, the first iteration usually does too.

Reducing PCB Project First Iteration Failure Rates

Always Run Peer Reviews & DRC Checks

No engineer catches everything the first time. Peer reviews and design rule checks (DRCs) are the cheapest insurance against simple but catastrophic mistakes. A second set of eyes can spot a swapped pin or missing net label before it becomes an expensive re-spin, and automated checks enforce manufacturability that even experienced designers sometimes overlook.

Prototype Critical Subcircuits Separately

Not every part of a PCB carries equal risk. High-speed interfaces, power converters, and sensitive analog sections are common failure points. Prototyping these blocks separately, on breakout boards or small test PCBs, allows teams to debug issues in isolation before committing to a full system build—saving months of wasted effort if something doesn’t behave as expected.

Use Proven Reference Designs Instead of Reinventing the Wheel

Most first-spin failures happen in areas that have already been solved a hundred times before—voltage regulators, oscillator circuits, communication buses. Reinventing these from scratch invites unnecessary risk. By leaning on proven reference designs, engineers can avoid hidden pitfalls and focus their energy on the truly novel parts of the project.

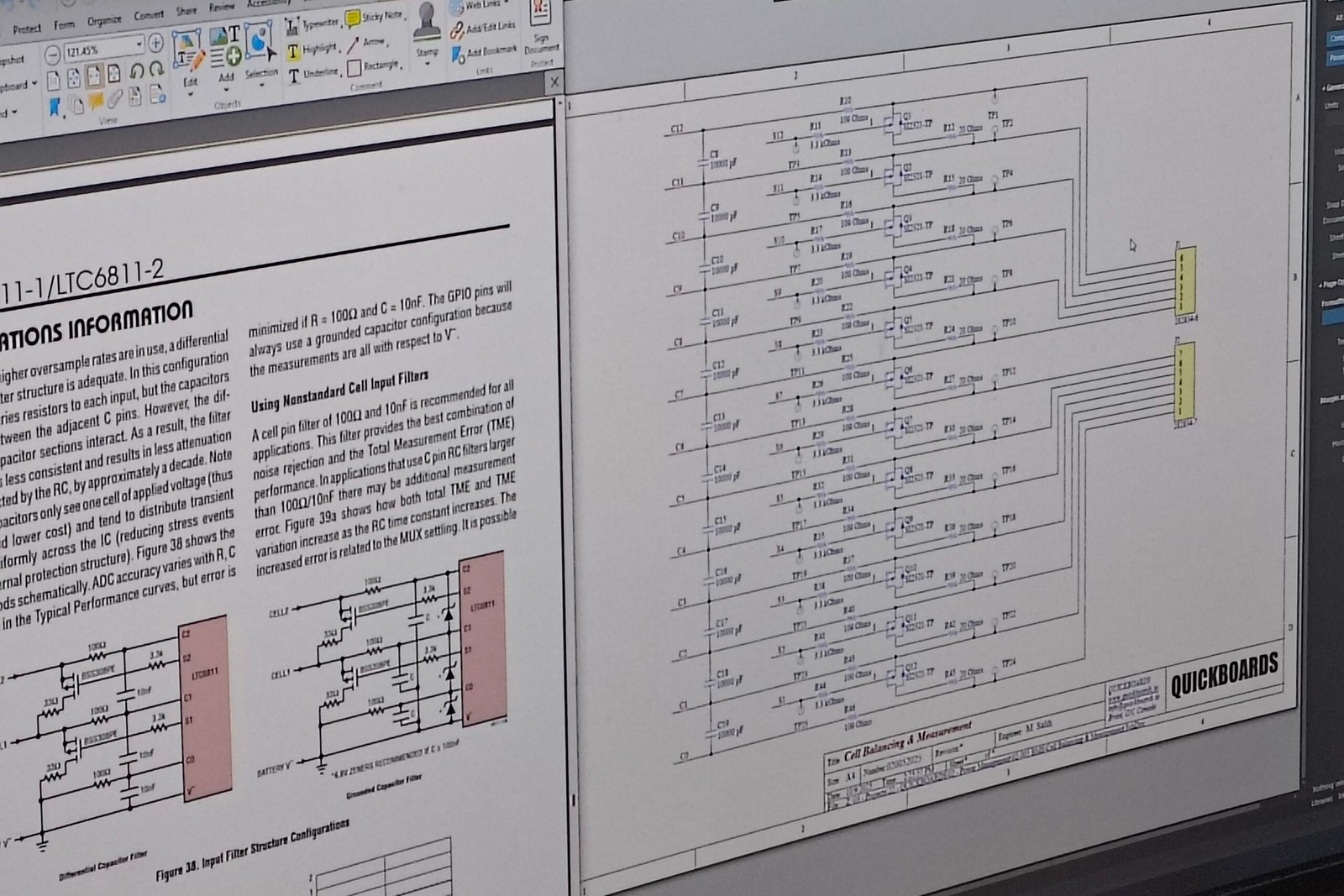

Leverage Quickboards to Cut Development Risk

Quickboards takes the idea of reference design one step further. Instead of piecing together scattered datasheet examples, engineers can drop in pre-verified schematic and firmware blocks that are ready to integrate in your ECAD tool of choice. From microcontrollers to power management to sensors, each block has already been validated, cutting design effort in half and massively improving the odds of a successful first spin.

The role of iteration in Hardware Development

In hardware design, achieving a “perfect” first spin is quite rare. Complex systems almost always reveal surprises when theory meets the real world. That’s why most experienced teams view early spins not as failures, but as critical learning opportunities. The first board helps validate assumptions, highlight weaknesses, and provide the data needed to refine the design.

That doesn’t mean you should accept wasted time and money as inevitable. By adopting best practices—peer reviews, focused prototyping, and using proven design blocks—you can dramatically reduce the number of unknowns that make first iterations risky. The goal isn’t to eliminate iteration altogether, but to make each spin a stepping stone rather than a setback. With tools like Quickboards, engineers start from a foundation of pre-verified schematic and firmware blocks, which shifts iteration away from fixing preventable mistakes and toward fine-tuning performance.

Designing for success, Not re-spins

The truth is, iteration will always be part of hardware design—but failure doesn’t have to be. By paying attention to component selection, power and signal integrity, layout discipline, and cross-team communication, you can dramatically reduce your risk of a re-spin.

Even better, you don’t have to start from scratch. With Quickboards, you can drop in pre-verified schematic and firmware blocks for microcontrollers, power management, sensors, signal acquisition and more—accelerating your design while avoiding common mistakes.

the points about schematic and layout oversights hit home, been burned too often

Are there any simulation software that can test a circuit in design before fabrication>?

neat