Industry Insights

Arduino Alternatives for Professional Prototypes: How Quickboards Bridges the Gap

When you outgrow hobby boards, you need Arduino alternatives for professional prototypes—solutions that don’t buckle under real timelines, real constraints, and real customers. The moment you move from breadboard to Bill of Materials, the cracks appear: performance ceilings, memory limits, reliability gremlins, and a design process that burn hours on rework instead of progress.

Quickboards closes that gap. It’s a modular Hardware-Schematic-Firmware ecosystem that preserves Arduino-style speed while delivering the rigor engineers demand—production-ready schematics, reusable blocks, and firmware that drops into professional toolchains without a fight.

Why Arduino Is Not Enough for Professional Hardware Development

Arduino rewired how the world learns electronics. It pulled embedded systems out of the lab and into classrooms, garages, and startup lofts—wrapping complexity in an interface anyone could use. By hiding the gnarly parts of firmware and hardware, it turned intimidation into curiosity.

For rapid tinkering, it’s still a masterpiece. But the moment a project edges toward commercialization—deadlines, compliance, production runs—that same simplicity becomes friction. Arduino’s strength in education turns into its bottleneck in engineering.

The Hobbyist Roots of Arduino

Arduino was never built for industry—it was built to democratize electronics. With open-source hardware, sprawling community libraries, and friendly C/C++ wrappers, it invited anyone to light an LED or poll a sensor in minutes. What once required an engineering degree could now be done on a weekend.

Makerspaces thrived. Classrooms lit up. Startups sprinted from idea to demo with astonishing ease. But that simplicity comes with a ceiling. The same abstractions that make Arduino approachable also blur the fine-grain control professionals depend on—timing accuracy, power budgets, memory management, and deterministic performance. In the real world, where cost, reliability, and certification rule, convenience often becomes constraint.

Where Arduino Projects Hit Their Limits

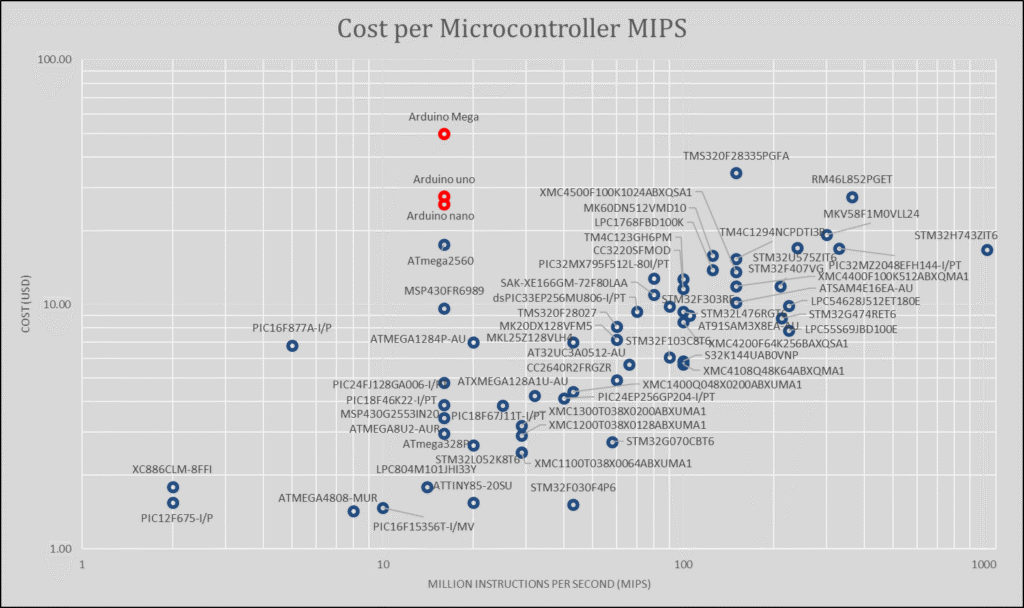

Beyond the comfort zone of hobby projects, Arduino’s cracks start to show. These boards are built for flexibility, not efficiency — and nowhere is that more obvious than in their cost-per-performance ratio.

The chart below compares dozens of mainstream microcontrollers by cost per MIPS (million instructions per second). The result is telling: Arduino Mega, Uno, and Nano sit far above the trendline, delivering a fraction of the processing power at several times the price. In other words, engineers are paying premium dollars for entry-level speed.

When your design demands faster sampling, tighter control loops, or deterministic timing, the Arduino platform quickly becomes the bottleneck. Its limited clock rates and modest memory can’t compete with purpose-built MCUs from Microchip, ST, or NXP — devices that deliver ten to fifty times more compute for the same cost.

Hardware constraints deepen the problem. Arduino’s pinouts and I/O configurations weren’t designed for industrial peripherals like CAN, HSPWM, or QSPI. The moment you step beyond simple sensor polling, you’re forced to pile on shields and breakout boards — each one adding noise, latency, and cost.

And then there’s scalability. Shield stacking might pass in a makerspace, but it doesn’t survive a product enclosure or an EMI test. What began as a neat proof of concept turns into a tower of compromises.

The Cost and Time Penalty of Staying on Arduino

Turning an Arduino prototype into a production-ready product is rarely a straight path — it’s a re-engineering marathon. The schematic must be redrawn for manufacturable PCBs, consumer-grade parts swapped for industrial components, and firmware rewritten to fit professional toolchains like MPLAB, STM32Cube, or Atmel Studio. What once took hours on a breadboard suddenly eats months in CAD and code.

Every iteration adds friction. Each redesign pushes deadlines. And for startups or design consultancies, those delays aren’t just inconvenient — they’re expensive. Burn rates rise, momentum fades, and opportunity windows close.

Arduino remains brilliant for sparking ideas, but it’s not built for finishing them. The moment you cross from prototype to production, its convenience collapses under the weight of real-world constraints.

For engineers seeking Arduino alternatives for professional prototypes, this rework loop becomes the deal-breaker — the signal that it’s time for something faster, cleaner, and built for the long haul.

The Gap Between Arduino Prototypes and Production-Ready Designs

That satisfying moment when a breadboard finally “works”? It’s a trap. In truth, the hardest work starts right after success. The prototype-to-product gap is where most engineering hours vanish — the space between a blinking LED and a board that can pass EMC, survive outside the lab, and scale to a thousand units.

Bridging that gap means abandoning the comfort of hobby boards and rebuilding everything from scratch. Connectors change. Layout rules tighten. Power, signal integrity, cost, BOM stock, production status and manufacturability all demand new attention. What looked like progress on the bench becomes a mountain of re-engineering before a single production board can ship.

From Breadboard to PCB: Why Re-Engineering Happens

Breadboards are forgiving; PCBs are not. Arduino shields rely on loose conventions — generic headers, flexible pinouts, jumper wires that make almost anything work once. But that freedom vanishes the moment you open Altium or KiCad.

To move from prototype to production, the schematic must be rebuilt, not imported. Pin assignments shift, footprints change, and routing rules tighten to meet clearance, impedance, and manufacturability standards. What worked on the bench now demands precision.

This is where many projects grind to a halt. Engineers find themselves redrawing circuits that already worked, burning time and budget on translation instead of innovation.

Firmware Porting Challenges

Arduino’s elegance comes from its layers of abstraction — wrappers that turn hardware complexity into friendly functions. It’s brilliant for beginners, but those same layers hide the low-level control professionals eventually need.

When engineers step up to bare-metal development in MPLAB, STM32Cube, or Code Composer Studio, the façade falls away. Much of the Arduino codebase can’t make the trip. Functions that once seemed universal — analogRead(), millis(), attachInterrupt() — unravel into device-specific register work.

Timers behave differently. Interrupt vectors shift. Peripheral initialization changes from chip to chip. The net effect? Firmware that looked portable must be rebuilt from scratch, line by line. What began as a weekend project becomes a full rewrite — another round of lost time before the hardware ever leaves the bench.

BOM and Component Lifecycle Issues

Hidden beneath every Arduino board and shield is a quiet risk: the bill of materials. Many of its ICs are consumer-grade parts chosen for accessibility, not longevity. They’re perfect for learning and prototyping — until one quietly goes end-of-life.

For commercial hardware, that’s a nightmare. A discontinued MCU, regulator, or USB interface can freeze production, trigger expensive redesigns, and ripple through your supply chain overnight. Professional engineers plan around component longevity, not convenience — parts with 10- to 15-year production commitments, stable datasheets, and second-source options.

That level of reliability simply isn’t guaranteed in the hobbyist ecosystem. What works for a one-off prototype rarely scales to a product line expected to live for years in the field.

What Professionals Look for in an Arduino Alternative

For engineers building real products, the right Arduino alternative isn’t about faster clock speeds or cheaper chips — it’s about design maturity. The ideal platform is purpose-built for performance, cost efficiency, scalability, and longevity. It needs to move as fast as a prototype but behave as solidly as production hardware.

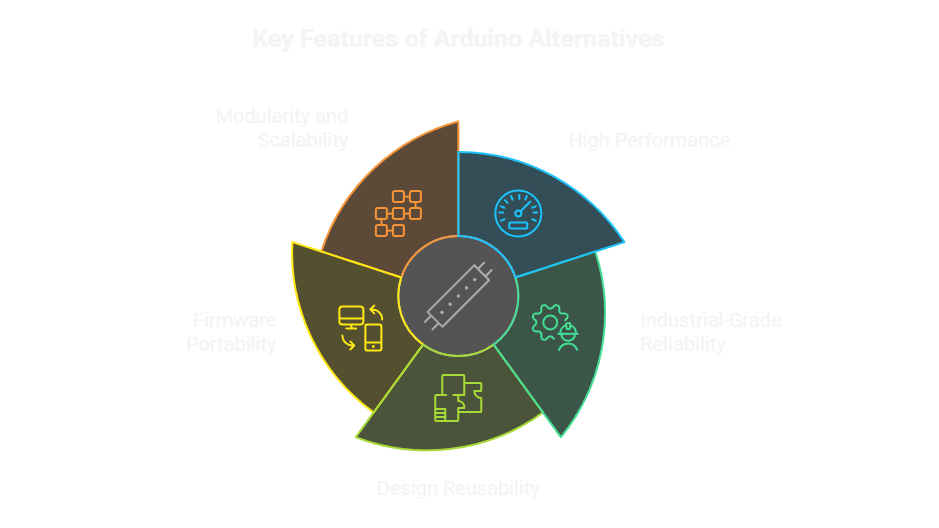

High Performance

Performance isn’t just a luxury — it’s what keeps firmware lean, loops tight, and deadlines met. Professional engineers measure efficiency in MIPS per dollar, and that’s where Arduino platforms quickly fall behind.

Many modern microcontrollers offer ten to fifty times more compute power at a fraction of the cost per instruction, with built-in DSP, DMA, and floating-point capabilities that Arduino boards simply can’t match. The difference isn’t theoretical; it’s measurable in faster sampling rates, lower latency, and tighter control loops.

A true Arduino alternative must deliver high throughput without compromise — robust clock speeds, optimized peripheral access, and the performance headroom to handle signal processing, communication stacks, and control logic simultaneously.

Industrial-Grade Reliability

Professionals design for tomorrow’s deadlines and tomorrow’s supply chains. They expect components with long-term availability, stable electrical characteristics, and predictable thermal behavior — parts that keep performing after thousands of hours in the field. That means MCUs and ICs with proven production histories, often carrying automotive- or industrial-grade ratings, not whatever happens to be trending on maker forums.

Design Reusability

Speed comes from reuse, not repetition. A professional ecosystem must let engineers drag and drop proven circuit blocks straight into their CAD environment — complete with verified footprints, decoupling networks, and layout guidelines. Each reusable schematic is a time credit earned: fewer redraws, fewer errors, and a lower chance of a first-spin failure.

Firmware Portability

Hardware only matters if the firmware keeps pace. Every schematic should be paired with firmware that just works — drivers and libraries ready for integration with professional IDEs like MPLABX, STM32CubeMX, or TI’s Code Composer Studio. Portability means you’re not rewriting initialization code or chasing register definitions every time you switch MCU families.

Modularity and Scalability

In the professional world, modularity isn’t a convenience — it’s a strategy. Engineers want architectures that scale across projects: mix-and-match MCU, power, and sensor blocks without touching the entire schematic. True modular design turns each circuit into a reusable asset, letting teams evolve products instead of reinventing them.

The best Arduino alternatives for professional prototypes embody these principles — built on proven components, backed by reusable design libraries, and supported by firmware that scales far beyond the hobby bench.

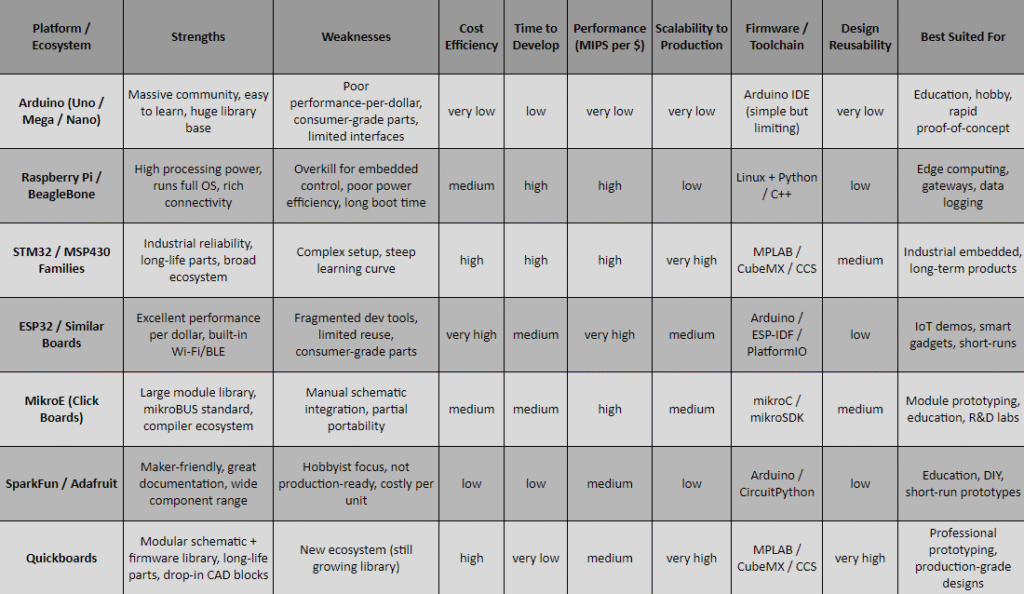

Exploring Common Arduino Alternatives (and Their Trade-Offs)

Before we get to the better solution, it’s worth surveying the landscape. The market is flooded with boards that promise to go “beyond Arduino,” and many do — in performance, connectivity, or toolchain sophistication. But few translate easily into production-ready hardware.

Raspberry Pi and BeagleBone

For Linux-based control, data logging, or IoT gateways, Raspberry Pi and BeagleBone are heavy hitters. They deliver raw power, community support, and full operating systems.

But that strength is also their weakness. Boot times, kernel dependencies, and OS instability make them poor fits for deterministic or low-latency control. Power efficiency? Forget it. These boards are phenomenal for edge computing, not for real-time embedded design.

PIC24, STM32 and MSP430 Platforms

At the professional end of the spectrum sit families like PIC24, STM32 and MSP430 — the industry’s workhorses. They’re backed by mature toolchains, broad peripheral sets, and long production lifespans.

The catch? Complexity. Configuring clock trees, timers, and peripherals is non-trivial. Getting a UART or PWM working the first time often means a weekend of datasheets and debugging. For teams on tight timelines, the learning curve is steep and the bring-up time can dwarf early-stage momentum.

ESP32 and Similar Boards

If you’re chasing value per dollar, the ESP32 and its cousins look unbeatable. Dual-core performance, Wi-Fi and Bluetooth built in, a thriving open-source community — all for the cost of a takeaway lunch.

But development fragmentation is a constant headache. Toolchains vary, libraries conflict, and hardware documentation is inconsistent. Worse, the ecosystem leans toward disposable consumer gadgets rather than long-term production. Reuse and standardization are afterthoughts.

MikroE Ecosystem

MikroElektronika (MikroE) offers an impressive library of “Click Boards” covering sensors, converters, and interfaces — a modular approach that feels close to professional. Their mikroBUS standard is elegant and their compiler ecosystem is extensive.

Yet despite the breadth, integration is still manual. Engineers must adapt schematics, rework footprints, and modify firmware from the Click compiler due to compatibility issues. It’s modular, yes — but not seamless. The concept stops short of bridging the prototype and product.

SparkFun and Adafruit

Then the maker world’s backbone: SparkFun and Adafruit. Their circuits, kits, and breakout boards make experimentation delightful and education accessible. They’ve done more than anyone to nurture the modern hardware community.

But these ecosystems are inherently project-oriented, not production-oriented. Their parts favor convenience over cost, layout over lifecycle. They’re ideal for learning, proof-of-concept demos, or short-run builds — not for repeatable, certifiable, scalable hardware development.

Why None Fully Solve the Transition Problem

Every one of these ecosystems solves part of the Arduino problem — whether it’s performance, flexibility, or accessibility. But none fix the prototype-to-production workflow.

They might give you higher processing power, or a slicker toolchain, but you’re still redrawing schematics, reassigning pins, and rewriting firmware to match production constraints.

What professionals need is an end-to-end ecosystem — one that unites schematic reuse, firmware portability, and production-ready modularity.

That’s where Quickboards comes in: the first platform designed to make the jump from idea to manufacturable hardware without starting over.

Introducing Quickboards: The Bridge Between Prototype and Production

What Are Quickboards?

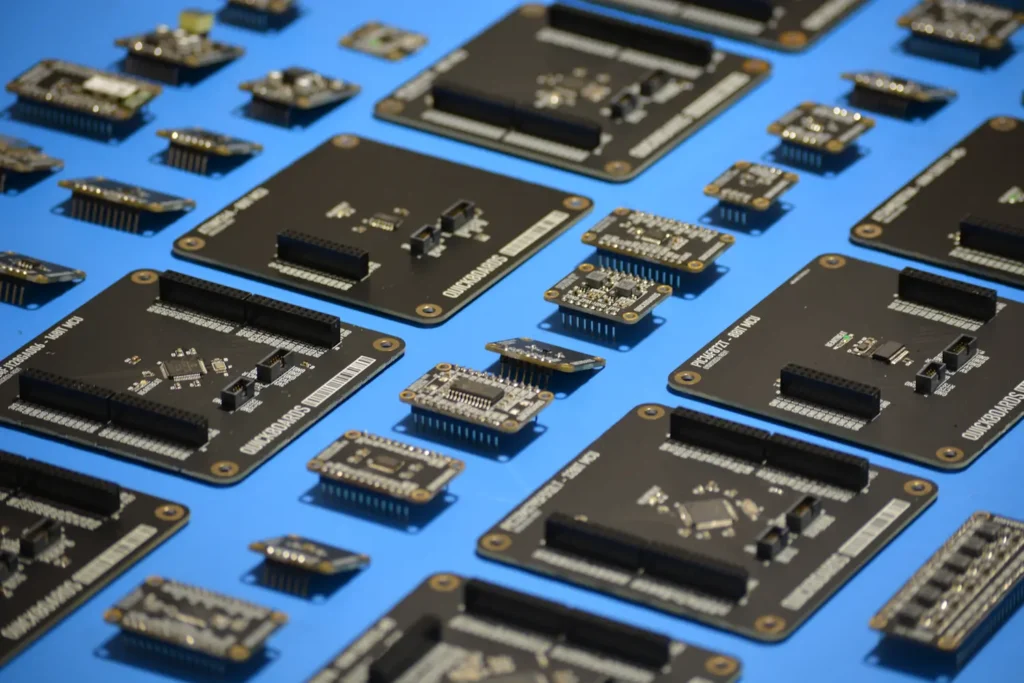

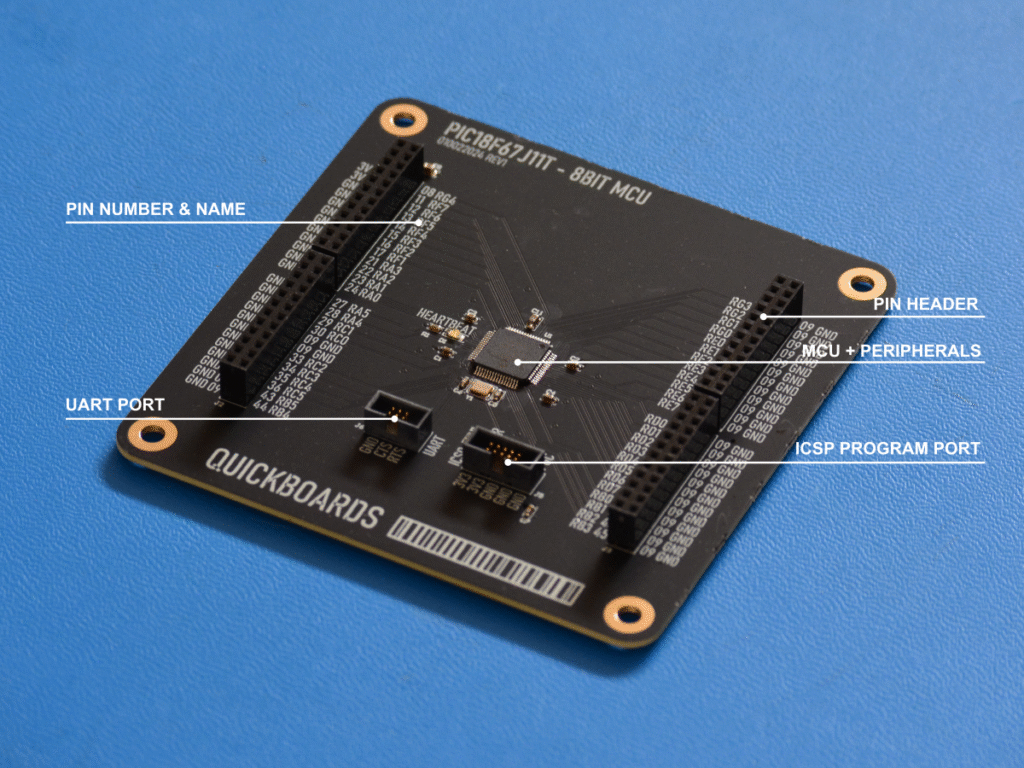

Quickboards is where modular thinking meets professional engineering. It’s a library of hardware, schematic and firmware blocks—each one a complete, verified circuit built to drop directly into your workflow. From microcontrollers and power converters to amplifiers and sensors, every block comes with its own downloadable schematic and matching firmware driver.

Each schematic also exists as a physical development board, letting engineers prototype and validate in hardware before committing to layout. Just build, test, and scale—seamlessly.

Build Faster with Verified Reference Designs

Why start from a blank schematic when proven circuits already exist? Quickboards lets you copy-paste verified reference designs straight into Altium, KiCad, or Eagle. Each block is tested for signal integrity, power stability, and noise performance—real engineering metrics that matter when your goal is a first-spin success, not a re-spin apology.

Every module you import eliminates hours of symbol creation, footprint checks, and datasheet cross-referencing. It’s speed with confidence built in.

Modular Firmware Integration

Hardware is only half the equation. Each Quickboard block includes a firmware driver—pre-configured for professional environments such as MPLAB X, STM32Cube, or Code Composer Studio.

Whether you’re spinning up a PIC, dsPIC, SAMD, or STM32, the firmware drops in cleanly. Initialization, communication, and peripheral control are already handled. No more wrestling with configuration bits or debugging register mismatches—just compile, connect, and go.

Open, Reusable, and Production-Ready

Quickboards are built for the long game. Every design uses industrial and automotive-grade components with multi-year availability guarantees. BOMs are optimized for supply stability, not convenience.

Each block is open, editable, and interoperable across major ECAD platforms, so you can adapt it to your exact design language. Once integrated, it becomes part of your reusable design library—ready for the next project, not forgotten in a folder.

Unlike other Arduino alternatives for professional prototypes, Quickboards isn’t just a faster board—it’s a complete modular design ecosystem that connects the simplicity of prototyping with the structure and reliability of production.

How Quickboards Accelerates Professional Prototyping

Cut Design Time by 60%

In traditional development, the clock starts long before the code does. Symbol creation, pin mapping, decoupling choices, and firmware initialization quietly eat up days—or weeks.

Quickboards wipes that slate clean. Every block arrives ready to drop into your design, with schematic symbols, footprints, and firmware pre-verified. Engineers skip the setup grind and jump straight into building real functionality.

Reduce Project Risk

Every Quickboard is validated in both hardware and firmware. Power rails are stable. I/O configurations are tested. Peripheral drivers are known to compile and run. That means no surprises at bring-up—and far fewer first-spin failures, the silent killers of project timelines.

For design firms and startups, this validation isn’t just convenience—it’s risk management. Each reused block is a block of confidence.

From Concept to PCB in Days, Not Months

Quickboards are built for plug-and-play integration. Entire subcircuits—MCUs, sensors, power stages—can be imported directly into Altium, KiCad, or Eagle, producing a functional schematic in hours.

Instead of waiting months to validate a new board, engineers can move from idea to assembled prototype in a single development sprint. It’s not rapid prototyping anymore—it’s professional prototyping, accelerated.

Works Across Multiple MCU Families

No lock-in, no silos. Quickboards supports PIC, dsPIC, SAMD, STM32, and more. You can choose the MCU family that fits your project’s performance, cost, or power target without overhauling your design flow. The schematic blocks stay consistent; only the silicon changes.

Works Across Multiple ECAD Tools

Quickboards plays well with others. Whether your team runs Altium, KiCad, or Eagle, each block drops cleanly into your environment. There’s no proprietary formatting, no forced platform, no hidden ecosystem traps.

It’s engineering freedom by design—a library that moves with you, not one that fences you in.

Get Started with Quickboards

Browse the Library

Explore hundreds of modular blocks across key categories — microcontrollers, power management, sensors, signal conditioning, and more — each ready for download.

Download and Integrate

Simply download the schematic files and drop them into your preferred CAD tool. All footprints, net names, and ports make integration seamless.

Build and Customize

Modify only what you need. Add your company-specific components or tweak parameters while keeping the proven Quickboards backbone intact.

Join the Community

Access tutorials, updates, and an affiliate rewards program that lets engineers share Quickboards and earn from referrals. The Quickboards ecosystem is for collaboration and continuous growth.

Final Thoughts: Bridging the Prototype-to-Product Divide

Arduino helped millions start their journey into embedded design. But when it’s time to build something professional, engineers need more control, reliability, and scalability.

Quickboards bridges that gap.

It takes the modular simplicity that made Arduino successful and upgrades it for professional use — with verified schematics, firmware drivers, and production-grade components.

Engineers shouldn’t have to restart designs from scratch.

With Quickboards, your next prototype can be your first production-ready design.

If you’re ready to move beyond Arduino and explore Arduino alternatives for professional prototypes, Quickboards gives you the fastest path from concept to production.

Frequently Asked Questions

Arduino boards are great for learning and quick proof-of-concepts, but they fall short in performance, reliability, and scalability. Their consumer-grade parts and limited interfaces make them hard to transition into commercial hardware. Professional engineers need alternatives that offer higher processing power, long-term component availability, and design reusability — exactly what Quickboards provides.

Platforms like STM32 and ESP32 deliver better performance, but they still require engineers to start from scratch when designing schematics and firmware. Quickboards solves this by providing pre-verified schematic blocks and modular firmware drivers, so you can drop entire circuits directly into your CAD tool. It bridges the gap between experimentation and production instead of just replacing the board.

Yes. Quickboards supports Altium, KiCad, and Eagle, with each block formatted for seamless import. You don’t need to change your toolchain or workflow — you simply download, integrate, and build.

Quickboards includes schematic and firmware support for popular MCU families such as Microchip PIC and dsPIC, Microchip SAMD, and STMicroelectronics STM32. The goal is flexibility: you can choose the MCU that best fits your cost, power, or performance needs without redesigning your entire circuit.

Absolutely. Quickboards was designed for that exact scenario. Engineers can replicate their Arduino-level functionality using modular schematic blocks — like MCU, sensor, or power modules — that are production-ready. You get the same simplicity of Arduino prototyping but with industrial-grade components, reusable design files, and firmware built for professional IDEs.

Cool chart about cost per MIPS, but some appear to calculate Fosc as mips which is not always the case.

Will Quickboards support STM32?

This provides a solid foundation for understanding the subject.