Industry Insights

What is Rapid Prototyping in electronics? A Complete Guide for Engineers

Rapid prototyping is a development process that enables engineers and designers to quickly create, test, and iterate on hardware and firmware designs. By leveraging modular, pre-built circuit solutions, and adaptable software frameworks, teams can shorten the time from concept to functional prototype, ultimately reducing development costs.

Advantages of Rapid Prototyping

Rapid prototyping offers engineers and product teams a powerful advantage by dramatically improving the speed, flexibility, and reliability of the development process. Compared to traditional product development cycles—which can take months or even years—rapid prototyping enables quick iterations that shorten timelines and reduce risk.

Speed

Traditional hardware development cycles—often involving lengthy PCB fabrication, component sourcing, and manual testing—can stretch over several months. With rapid prototyping, especially using modular systems like Quickboards, teams can build and evaluate working circuits in just a few days. This accelerated iteration loop allows for real-time adjustments and faster decision-making, enabling products to reach the market well ahead of competitors.

Cost Efficiency

Early-stage errors in circuit design, layout, or firmware can be extremely expensive if discovered late in the development process. Rapid prototyping enables early validation of design choices, allowing teams to catch flaws before committing to costly tooling, assembly, or regulatory testing. It also reduces the need for multiple prototype revisions, saving both material costs and engineering hours.

Flexibility

In traditional workflows, making a change often requires a new PCB spin or even a complete redesign. Rapid prototyping platforms eliminate that friction. Engineers can easily swap out modules, test alternative components, or reconfigure system architectures without incurring delays or manufacturing overhead. This flexibility is especially valuable during proof-of-concept development, product pivots, or feature experimentation.

Risk Reduction

The earlier you identify problems, the cheaper they are to fix. By enabling physical testing in real-world conditions—power consumption, signal integrity, EMI, thermal performance—rapid prototyping helps teams uncover critical issues while they’re still manageable. It also facilitates early firmware integration and verification, reducing the risk of late-stage compatibility or performance surprises.

Better Communication

A functional prototype speaks louder than schematics or slide decks. Physical models allow engineers, product managers, stakeholders, and even non-technical decision-makers to evaluate a design’s look, feel, and performance. This improves alignment, accelerates approvals, and helps secure stakeholder buy-in, funding, or manufacturing partnerships with greater confidence.

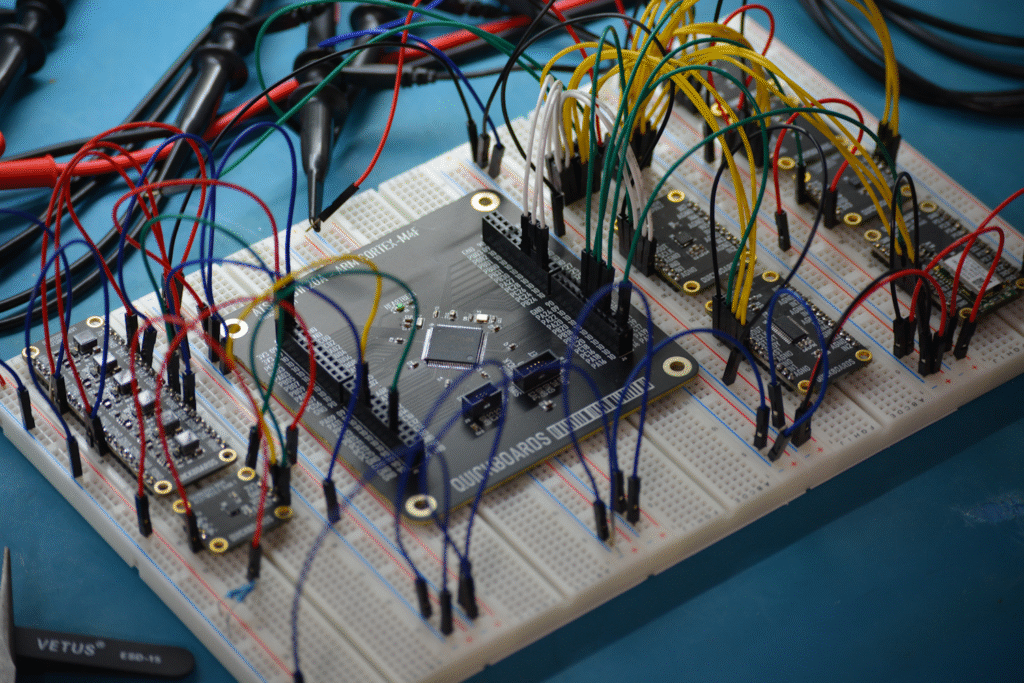

How Quickboards Enhance Rapid Prototyping

Quickboards are designed to streamline the prototyping process by providing pre-verified, modular circuit blocks that integrate seamlessly into various applications. Here’s how they help:

Plug-and-Play Modules

Quickboards eliminate the need for custom PCB fabrication during early development. Engineers can bypass the time-consuming layout, fabrication, and assembly steps by using pre-validated modules that connect seamlessly. This allows teams to focus on core functionality, testing, and iteration—rather than dealing with schematic capture and board design at every stage.

Reference Designs Built-In

Each Quickboard module acts as a proven reference design, based on real-world, production-grade ICs. This saves valuable engineering time normally spent on datasheet parsing, circuit validation, and firmware bring-up. Whether you’re working on power management, sensing, or communication, each block is ready to drop into your project with pre-vetted performance.

Modularity and Reusability

With their standardized form factor and interconnects, Quickboards are built to be reused. A single set of modules can support multiple product concepts or revisions, reducing both e-waste and development costs. When requirements change—as they often do in early-stage R&D—you can swap out blocks without starting over.

Compatible with Industry-Standard Tools

Quickboards are designed to integrate seamlessly with professional embedded development environments, including STM32 (via STM32CubeIDE), Microchip’s MPLAB X IDE, and Texas Instruments’ Code Composer Studio. Engineers can begin firmware development immediately using familiar toolchains, debuggers, and programmers. This reduces setup time and ensures compatibility with production-grade workflows right from the prototyping stage.

Designed for Scalability

Once your prototype is validated using Quickboards, the transition to final design is straightforward. Each module’s schematic is available for download for several ECAD tools (Altium, KiCAD & Eagle), making it easy to consolidate multiple blocks into a custom PCB. The modular prototype becomes the reference for your final design—saving engineering effort across both hardware and firmware.

Summary

By leveraging Quickboards, engineering teams can dramatically shorten their product development cycles while ensuring robust, well-tested designs. Whether you’re a startup building a proof-of-concept or an established company optimizing your R&D process, Quickboards provide a reliable foundation for faster, more efficient hardware innovation.

Want to see how Quickboards can accelerate your next project? Visit our library to browse a selection of modular hardware, schematic and firmware files that can accelerate your next project.